Stable supplier network a success factor

HUGO BOSS’ sourcing activities cover a wide range of apparel products and accessories in the premium and increasingly also in the luxury segment. To ensure the excellent craftsmanship and optimum availability of its products, the Company works with a stable network of experienced, specialized suppliers. Last year, the HUGO BOSS Group had active supply relationships with 257 contract manufacturers and suppliers of merchandise (2014: 281). The number of these partners was reduced again by optimizing capacity utilization. In the interests of minimizing risk, the procurement volume is spread over a global network of suppliers to reduce exposure to individual procurement markets and production facilities as far as possible. Consequently, the largest independent supplier accounted for only 9% of the Group’s entire procurement value (2014: 8%). Report on Risks and Opportunities

Business relationships dependent on strict adherence to labor and social standards

HUGO BOSS works solely with carefully selected partners that satisfy its stringent requirements. Adherence to strict labor and social standards is the prerequisite for the establishment of a business relationship. These are verified either on the basis of disclosures made by the supplier itself or on-site audits of the production facilities. In addition, HUGO BOSS’ social standards form a fixed element of the contracts signed with suppliers, compliance with which is reviewed in regular on-site audits. The results of the social audits are incorporated in the semi-annual supplier assessments and thus form the basis for the future collaboration with the partner in question. In addition to observance of strict social and labor standards, the ability to satisfy the high quality and craftsmanship requirements constitutes a further important criterion in the selection of suppliers. The supplier’s reliability, technical equipment and innovativeness, financial strength and cost efficiency are also taken into account. Sustainability

HUGO BOSS primarily uses fabrics and trimmings from Europe

HUGO BOSS differentiates its sourcing activities into raw materials, in-house production, contract manufacturing and purchased merchandise. The raw materials which it sources mainly comprise fabrics as well as trimmings such as lining, buttons, thread and zippers. Cotton, wool and leather are the most frequently used materials. The Group purchases most of the raw materials used in its own production or contract manufacturing from suppliers in Europe. Fabrics are predominantly sourced from long-standing partners in Italy.

For products made under contract manufacturing arrangements, HUGO BOSS provides suppliers not only with the patterns but also with the fabrics and trimmings required. Coats, sportswear jackets, suits, jackets and trousers are primarily made under contract manufacturing arrangements. These are product groups that demand particularly advanced production skills and technical facilities of the supplier. HUGO BOSS mainly works with companies in Eastern Europe in these segments.

Sportswear products are primarily sourced as merchandise and include items such as T-shirts, polo shirts and jeans. With this kind of sourcing, the suppliers are mostly based in Asia, Eastern Europe or North Africa and are provided with the necessary patterns by HUGO BOSS. However, they independently source their own raw materials, i.e. fabrics and trimmings.

With the exception of the classic shoe collection that is produced at the Group’s own factories in Italy and Poland, shoes and leather accessories are mainly sourced from business partners in Asia and Europe. Particularly high-quality leather accessories such as articles for the menswear “Signature” range or bags and accessories for the iconic “Bespoke” womenswear range are produced by leather specialists in Italy and finished with hand-made details.

HUGO BOSS products primarily manufactured in Eastern Europe

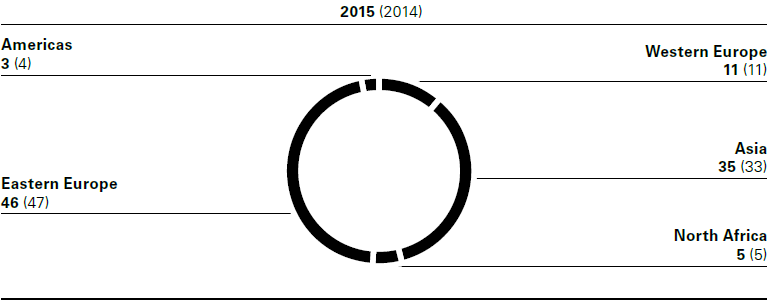

In value terms, Eastern Europe (including Turkey) accounts for 46% of the total procurement volume (2014: 47%) and thus remains the Group’s most important procurement market. The Group’s own factory in Izmir plays a key role here, accounting for 15% of the total volume sourced (2014: 15%). 35% of products are sourced from external suppliers in Asia (2014: 33%). Within Asia, China is by far the most important procurement market. The remaining goods are sourced from Western Europe (11%; 2014: 11%), North Africa (5%; 2014: 5%) and the Americas (3%; 2014: 4%).

The Group regularly reviews the regional optimization of its sourcing activities to respond effectively to any increase in costs in procurement processes, particularly as a result of higher wage expenses, and to react with optimum effect to any changes in industrial structures and production capabilities in individual markets.

Regional split of sourcing and production volume (in %)

Continuous intensification of collaboration with strategic suppliers

The Group has a keen interest in maintaining long-term strategic relationships with its suppliers. Close consultation between producers and the HUGO BOSS Group’s technical development department is crucial for ensuring a swift response to any market changes and for shortening lead times. Thus, suppliers’ production capabilities are factored into the product development process at a very early stage. Feedback from suppliers on the fabrics and patterns used in past collections is taken into account in new designs. Innovative processing methods are repeatedly tested in close collaboration with production partners to ensure the excellent quality of craftsmanship for which HUGO BOSS products are known all over the world. In the event of positive test results and economic viability, these processes are then rolled out for standard use by the partner facilities.

The Group is also continuing to intensify its joint activities with its main suppliers in the area of sustainability management. For example, the first ever HUGO BOSS Supplier Day was held for strategic suppliers at the Izmir facility last year. At this event, the HUGO BOSS sustainability program, which is to be implemented in conjunction with the suppliers, was presented. The resultant requirements, e.g. in connection with ensuring social standards, establishing professional environmental management and minimizing the use of chemicals and other potentially hazardous substances in production, were outlined together with an elaboration of the possibilities which HUGO BOSS has for assisting its partners in the implementation of the program. Sustainability